Treating Iron or Frac Iron

Plug valve

Check valve

Emergency relief valve

Circulating hose loops

Swivel joints

Pup joints

Pipe fittings

Hammer union |

Plug valves:

General description

Plug valve is designed and manufactured in line with API Spec 6A latest edition and used to isolate flow from either

direction, and can provide dependable service for applications

such as cementing, fracturing, acidizing, coiled tubing and sand

control.

Plug valve body is forged from high quality alloy steel

to offer super strength, and then machined to create plug valve

chamber, precision-ground plug is plated standard for maximum

corrosion protection, sealing are precisely ground to offer

excellent metal-to-metal seal between seal segments and plug,

precision-ground floating seal segments insure positive seal

between fluid stream and cylindrical plug, pressure-enhanced

sealing between segments and hammer plug valve body provided by

molded rubber static segment seal.

Plug valve features premium quality and quarter-turn, and designed and come

with thread or hammer union connection, such ensure that plug

valve can be easy for operation or maintenance with hammer. ULT Plug

valves can be available in three primary models in 1"¡Á2", 2" and

3" in size, 3" plug valve is often used in heavy duty service, cold working pressure range from 6,000 to

15,000 psi in both Standard and H2S service, so different components or parts with deferent pressure ratings of

hammer plug valves cannot be mismatched.

ACME connection of

hammer plug valve is often Fig 1502, Fig 1002, Fig 602, for

other connections of connection of hammer plug valve, contact

the manufacture.

Plug valve body and body cap can be joined by thread,

while flanged plug valve body with flanged body cap are available for

operator's option.

According to configuration, plug Valves can be available in three models: ULT model, LT model, and flanged connection

model.

According to operation, plug Valves can be available in manual operated, gear operated and hydraulic operated.

Each hammer plug valve is hydraulically tested prior to release

and each hammer plug valve is stamped with API monogram and

product S.N. for tracing, both ends of plug valve are protected by pin and box thread protector.

ULT plug valves

Connection of ULT plug valve can be hammer union and pipeline thread, union end connection type plug valve is also named in hammer plug valve or hammer valve. while pipeline thread of plug valve can be available in inner pipeline thread or outer

pipeline thread or outer and inner pipeline thread, pipeline thread type plug valve is often used in cementing head.

|

|

|

|

|

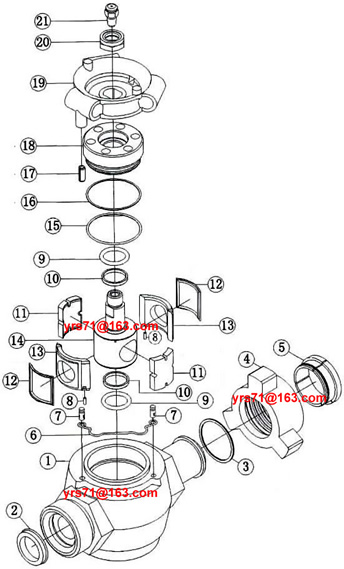

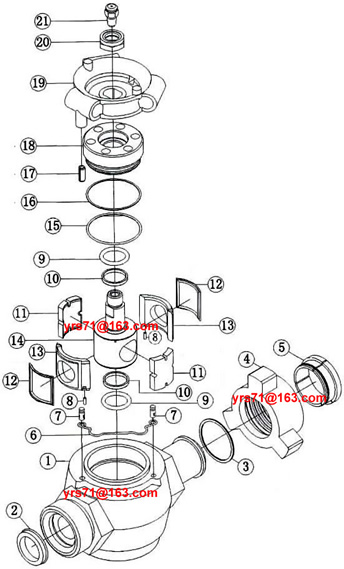

Description for configuration

S.N. |

Part name |

Qty |

1 |

Valve body |

1 |

2 |

Seal rubber |

1 |

3 |

Clip ring |

1 |

4 |

Wing nut |

1 |

5 |

Wing nut retainer |

3 |

6 |

Stop ring |

1 |

7 |

Stop ring pin |

2 |

8 |

Seal segment stop |

2 |

9 |

O-ring plug |

2 |

10 |

Packing |

2 |

11 |

Side segment |

2 |

12 |

Seal |

2 |

13 |

Seal segment |

2 |

14 |

Plug |

1 |

15 |

O-ring |

1 |

16 |

Back-up ring |

1 |

17 |

Stop pin |

1 |

18 |

Body cap |

1 |

19 |

Plug cap |

1 |

20 |

Nut lock hex |

1 |

21 |

Grease fitting |

1 |

From items 9 to 16 are repair kits |

plug valve repair kits

|

LT plug valve

Low torque plug valve or LT plug valve is a lubricated, tapered pocket, quarter-turn plug valve for rapid full open or close operation. The valve cavity is tapered to ensure uniform seating of the sealing inserts, providing a reliable seal at the full range of pressures.

LT Plug Valve and replacement parts are engineered to provide low operating toque and resistance to the toughest abrasive and corrosive conditions.

Connection type of LT plug valve can be hammer unions, line pipe or API flanged, API flanged connection plug valves can be hydraulic driven or manual operated.

Sizes of LT plug valve are available in 2¡± and 3¡±

LT Plug valve with hammer union connection

plug valve with handwheel

|